DDIA – Data Driven Immersive Analytics in Digital Industries

How Know Center & Partners are Opening New Paths in Industry with VR / AR

Introduction

In an increasingly interconnected industry, the demand for intuitive, interactive, and location-independent tools for data analysis is growing. This is precisely where the research project DDIA (Data Driven Immersive Analytics in Digital Industries) from the Know Center Graz comes in. The aim is not only to develop immersive analytics using Virtual and Augmented Reality (VR/AR) in theory, but also to make them tangible in real industrial use cases.

Partners & the Role of Alphagate

The industry partners include:

- Alphagate Automatisierungstechnik Gesellschaft m.b.H (Austria)

- Andritz AG (Austria)

- IMERYS Talc Austria GmbH (Austria)

- Siemens AG

Alphagate contributes its expertise in automation and industrial processes—an essential factor when immersive analytics solutions are to be integrated into real production environments. For example, connecting machine sensor data with visualization through AR/VR platforms. In the future, Alphagate plans to incorporate the insights gained from the DDIA project more strongly into its own machine operation projects, creating interactive, user-friendly solutions that offer operators a completely new way of interaction and analysis.

Project Content & Results

Some of the key aspects and developments realized within the project include:

Immersive analytics with digital twins:

Digital twins create a coherent experience that combines both real machines and plants with virtual AR/VR components. This allows users to interact with data both remotely and on-site.

VR/AR applications in practice:

- Imerys open-pit mining: Use of drones for data collection, with the goal of creating an immersive environment enabling remote analysis. Users can experience data visually and interactively.

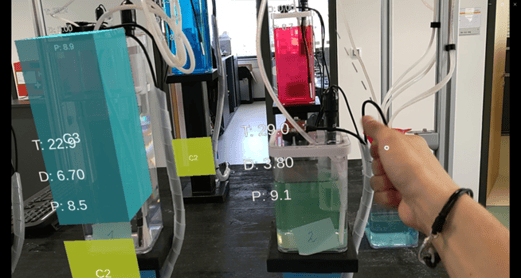

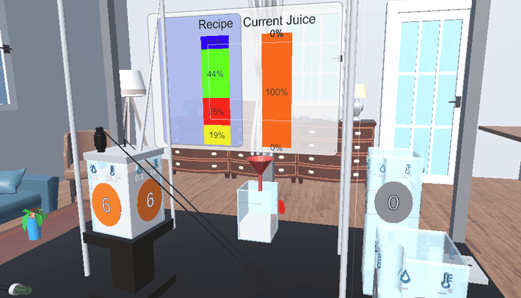

- Juice Mixer test stand: Development of a test stand accessible in real time. A HoloLens 2 app displays sensor data directly on containers and sensor sources. In addition, a digital twin was developed for training and maintenance purposes.

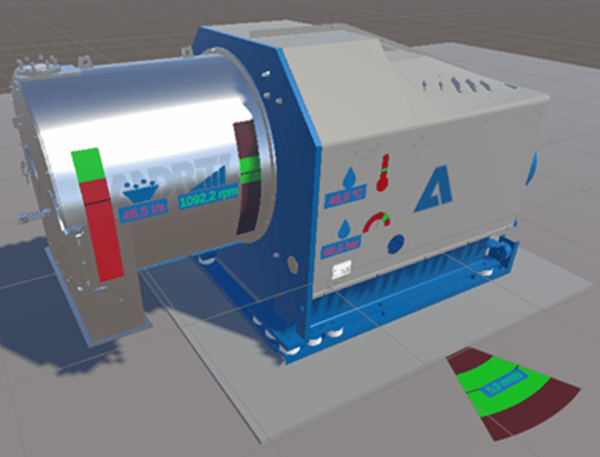

- Machine visualization at Andritz: Use of AR (e.g., HoloLens) to visualize sensor values on machines. Even though some data was simulated, feasibility and potential were successfully demonstrated.

Scientific contributions:

Several publications and conference presentations were produced within the project (e.g., ISMAR – International Symposium on Mixed and Augmented Reality).

Significance for Industry & Future Perspectives

The results of DDIA clearly demonstrate:

- Immersive technologies (VR/AR) are not just “nice to have,” but can deliver real value in many industrial use cases — such as maintenance, training, remote diagnostics, or process optimization.

- The combination of sensor data + digital twin + immersive visualization makes complex information more understandable and accessible — even for professionals who don’t use data analysis tools every day.

- Projects like DDIA foster interdisciplinarity: technology, design, user research, data science, automation — all must work together. As an industry partner, Alphagate helps build the bridge from research to real-world applications.

Alphagate’s Vision for the Future: Integration into Machine Operation

Alphagate will not only use the insights gained from the DDIA project as a one-time innovation but plans to integrate them continuously into future projects for machine operation. A particular focus lies on improving human-machine interaction.

Through the use of AR/VR technologies, Alphagate will be able to provide machine operators with a visual, interactive interface that goes beyond traditional displays. Operators can directly interact with machine information in a three-dimensional virtual environment, identify error sources more quickly, and make real-time decisions. This can be especially valuable for complex machines in manufacturing, automation, and mechanical engineering, where operators can access sensor data directly without relying on external devices or lengthy manuals.

Furthermore, the concept of the digital twin will be increasingly integrated into daily operations to monitor machine or plant performance in real time. In case of problems, operators can intervene immediately and use AR/VR tools to initiate solution steps. In the long term, this model will also be applied to training and maintenance processes to reduce costly downtime and failures.

Challenges & Open Questions

Of course, projects like this are not without challenges:

- Data integration & real-time capability: Sensor data must be reliable and available promptly, even under limited network conditions or latency issues.

- User-friendliness & usability: AR/VR interfaces must be intuitive, otherwise they won’t be adopted in practice.

- Costs & technological infrastructure: High-quality hardware such as HoloLens, drones, etc. is expensive and requires training.

- Scalability & maintenance: Solutions that work in specific demonstrations often need further robustness before they can be broadly deployed in production, maintenance, or training.

Conclusion

DDIA impressively demonstrates how immersive analytics with Virtual and Augmented Reality in industrial environments can move beyond vision to reality. With Know Center as research partner and companies like Alphagate, Andritz, Imerys, and Siemens as industry partners, the project shows how collaboration between research and practice yields real benefits.

For Alphagate, this project represents not only a milestone but also a decisive step in the further development of technologies for machine operation. The knowledge gained will not only be integrated into existing automation solutions in the short term but also form the foundation for future projects — enabling operators to interact with machines and production systems in even more immersive and interactive ways.

It will be exciting to see how these technologies evolve and shape the industry of the future — particularly as companies like Alphagate actively integrate these innovations into their solutions.